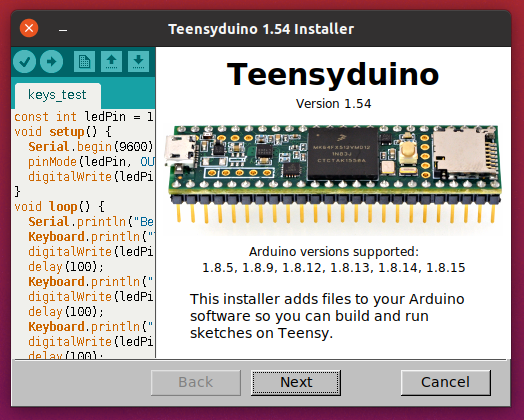

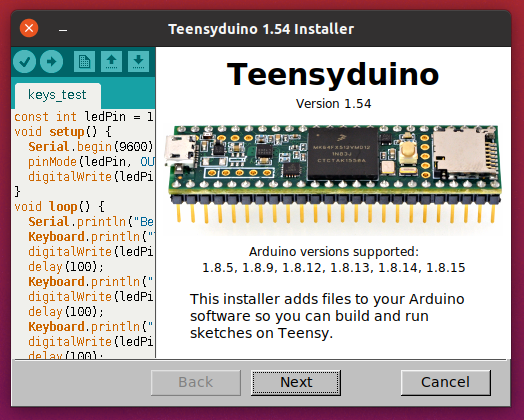

Teensyduino 1.54 was released earlier last week.

This article is a detailed look at the new & improved features version 1.54 brings.

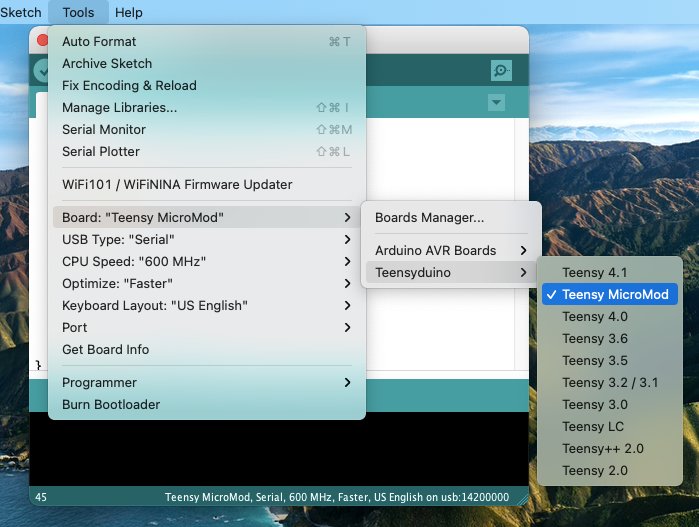

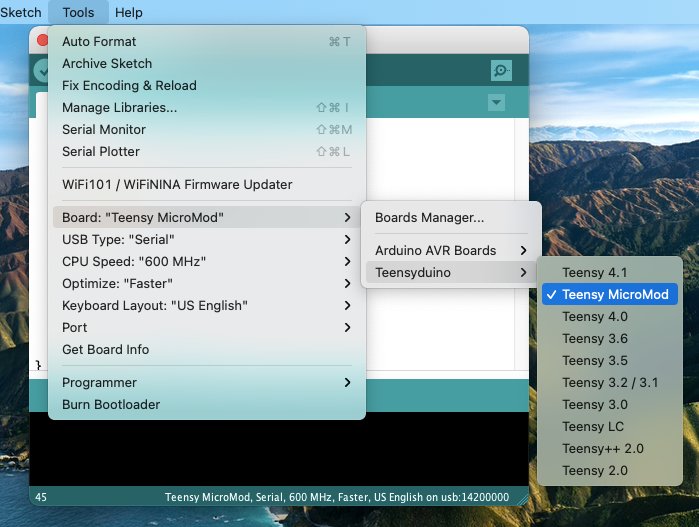

MicroMod Teensy Support

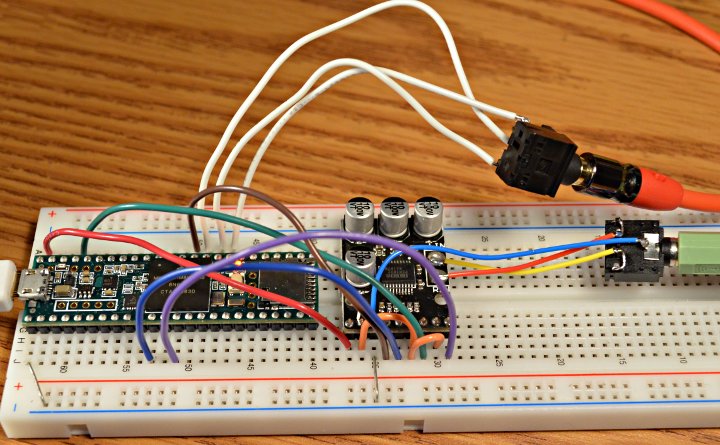

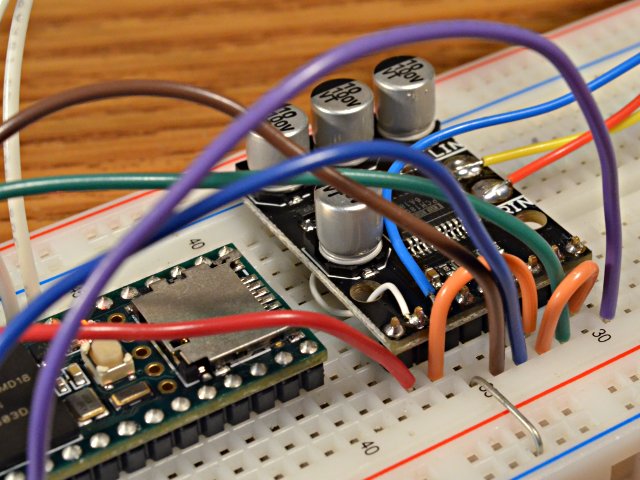

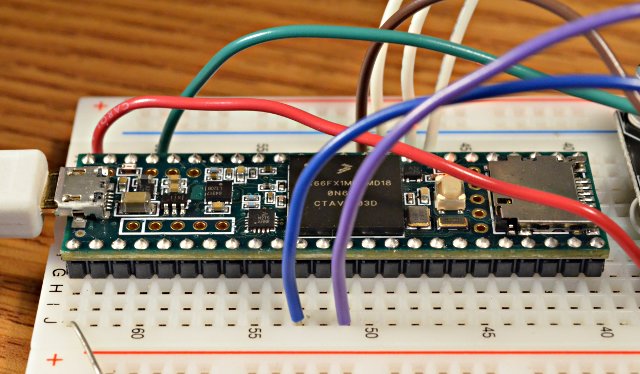

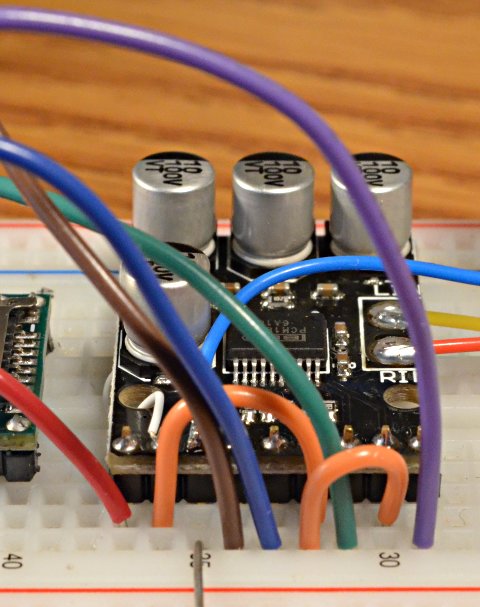

Sparkfun recently released MicroMod Teensy, which is a product of collaboration between PJRC and Sparkfun.

MicroMod Teensy has hardware similar to Teensy 4.0 (600 MHz ARM Cortex-M7, 1MB RAM), but with larger 16MB flash memory.

Teensyduino 1.54 brings full support for MicroMod Teensy. Simply select it from Arduino’s Tools > Boards menu.

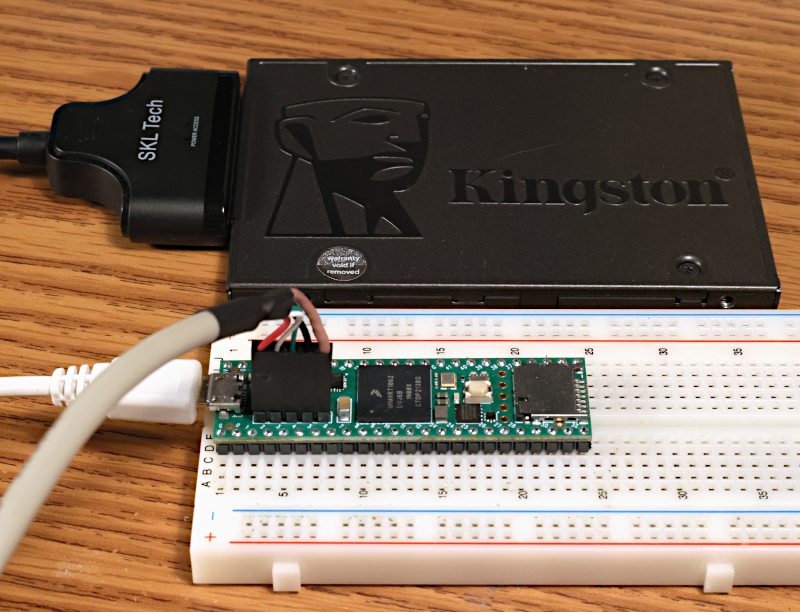

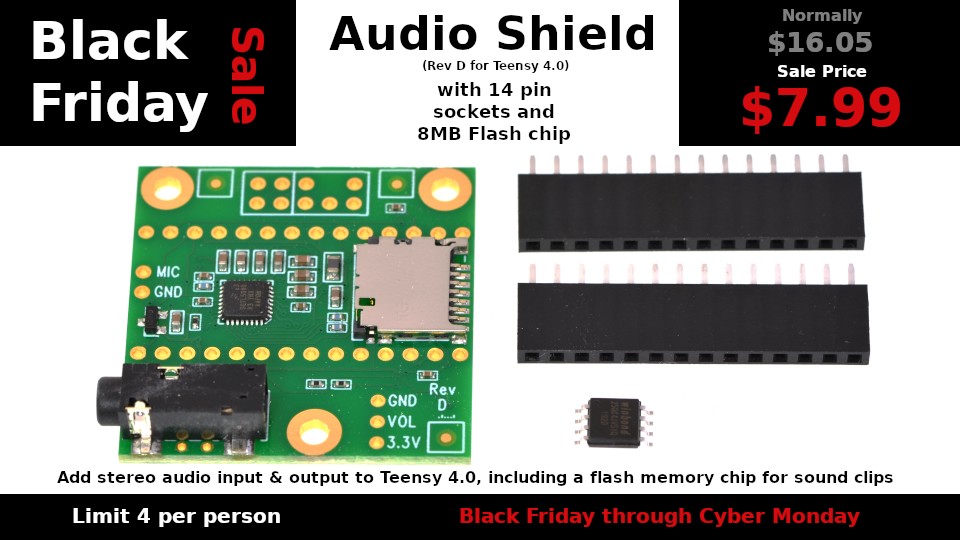

Teensy has traditionally focused on DIY electronics experimentation & building, particularly with solderless breadboards. While a few shields exist, like the Audio board, PJRC doesn’t have the resources to create a large ecosystem of shields & accessories. Almost all projects involve DIY building.

Sparkfun’s MicroMod form factor aims to give you an ecosystem of “just plug parts together” carrier boards and Qwiic I2C modules for a wide variety of projects. If any of Sparkfun’s growing collection of carrier boards is a close fit to your project’s needs, and you’d rather buy something than experience the joy and learning (but also frustration) of DIY building, MicroMod carrier boards may save you a lot of time.

MicroMod can also be useful for low volume production. Obviously at high volume you would create a fully custom design from the ground up, and at medium volume a custom PCB using the Teensy 4 bootloader chip can make good sense. But for low volume production, keeping up-front costs low and minimizing money tied up in inventory is often the best path to success. In those cases, you would manufacture a simple 2-layer PCB with as few expensive parts as possible, then populate it with Teensy and other complex modules at the time you actually sell.

Traditional Teensy requires through-hole header pins, which are simple but labor intensive to solder. MicroMod form factor allows you to build your PCB using an inexpensive M.2 socket. Then when you’re ready to sell a product, just buy the MicroMod board and plug it in.

Like all Teensy models, MicroMod Teensy is supported by Teensy Loader.

Teensy Loader is a stand alone program which can be used without the rest of Teensyduino and the Arduino IDE. When you need to program a large number of boards with the same firmware, load the HEX file and turn on Teensy Loader’s “Auto” mode. Then plug each board into a USB cable and press its Program / Boot button, or momentarily touch pads together if your custom PCB is made without a pushbutton. Auto mode immediately uploads your firmware without requiring any keystrokes or mouse clicks!

Arduino 1.8.15 Support

Arduino released Arduino IDE 1.8.15 on May 15, 2021, and also version 1.8.14 several days earlier.

Teensyduino 1.54 brings full support for these 2 latest (non-beta) versions of the Arduino software.

If you are unsure which version you have, click Help > About to check. On Macintosh, the About menu item is found under the program name rather than Help.

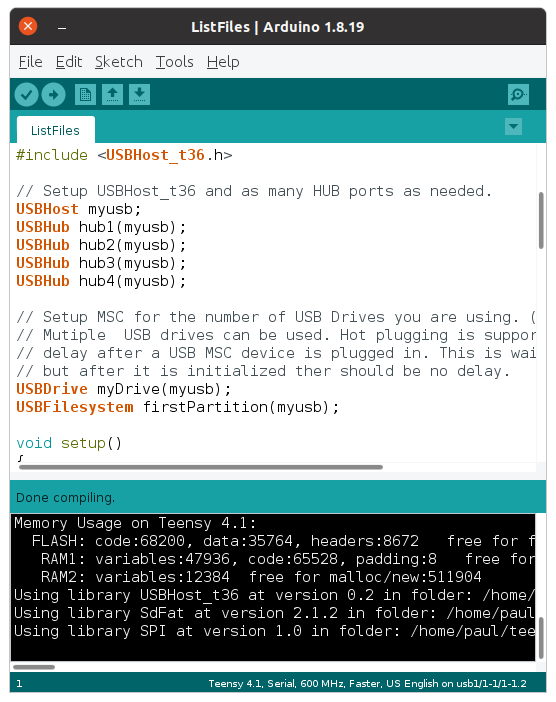

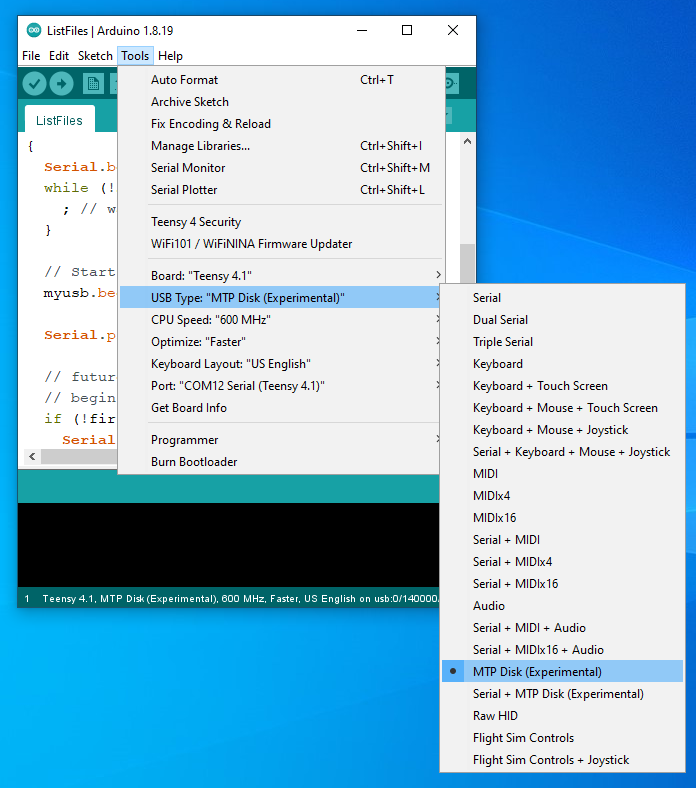

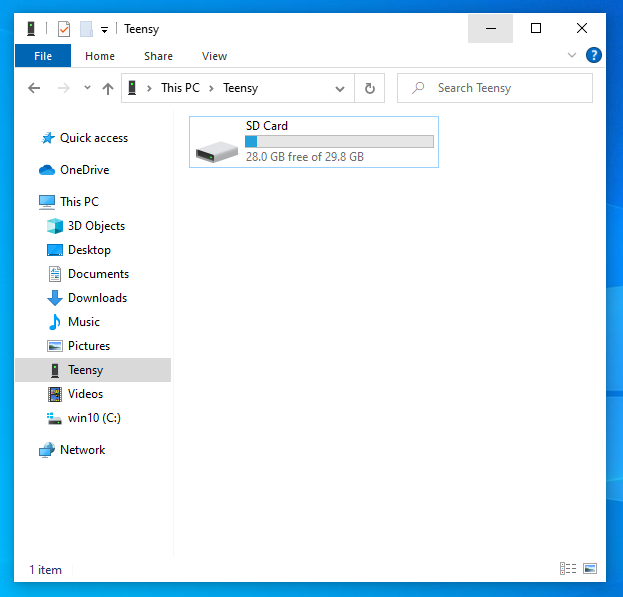

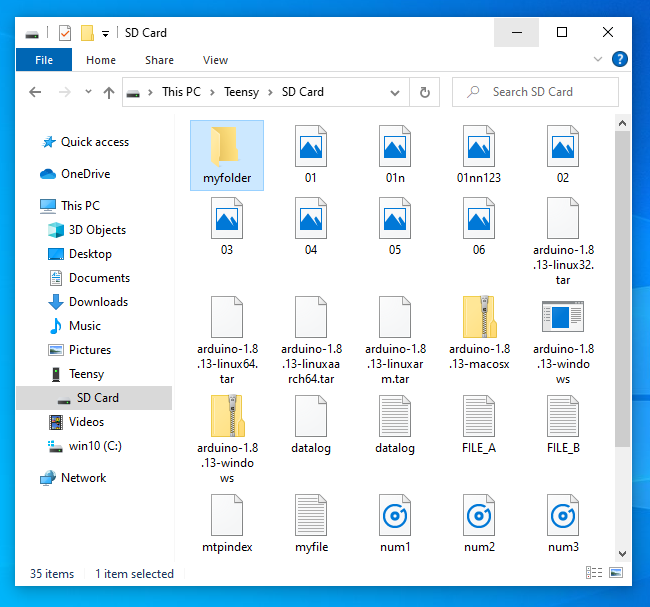

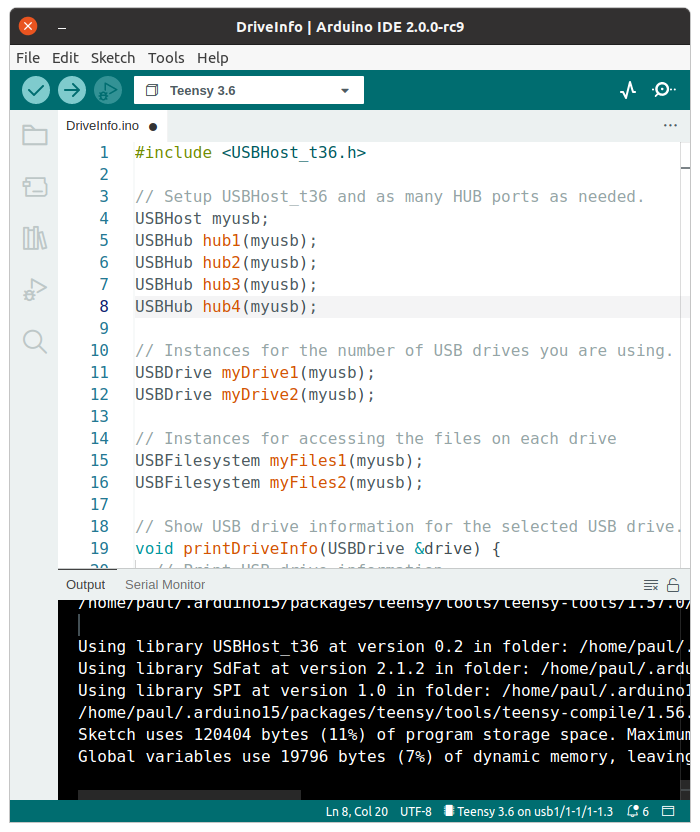

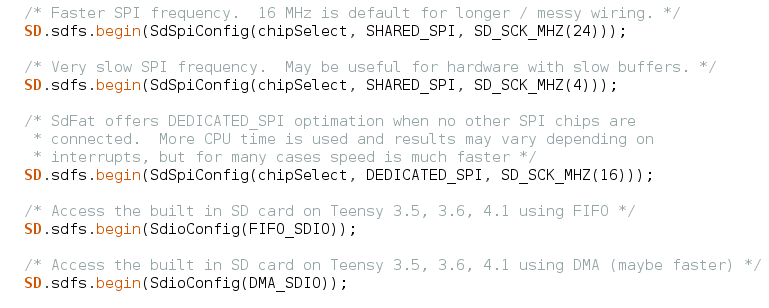

SD Cards Using SdFat with SD Library Compatibility

Until now, 2 different libraries were used to access SD cards. The old Arduino SD library is used by most programs. Bill Greiman’s SdFat library offers higher performance, support for large cards, and use of long filename rather than limited to 8.3 DOS filename format.

Teensyduino 1.54 has completely removed the very old Arduino SD library, which internally included an ancient version of SdFat.

SD.h has been replaced by a thin compatibility layer to allow all programs written to use the old SD library to still compile and function properly, but all SD card access is now actually performed with the SdFat library.

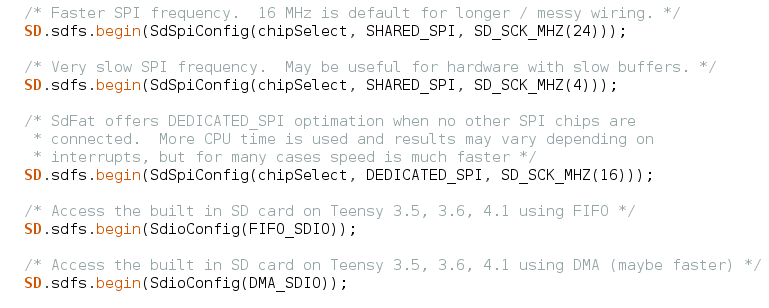

You can even mix usage of the traditional SD library and SdFat’s more capable API in the same program. To do this, use “SD.sdfs” to access the SdFat instance within the SD compatibility layer.

One of the most useful ways to mix APIs is calling SdFat’s begin(), with SD.sdfs.begin() rather than the simple SD.begin() which offers only a choice of which pin to use for CS. SdFat’s begin() lets you configure several hardware access optimizations.

After using any of these, the SD card can be accessed using either SD library functions, or SdFat functions, or a mix of both. For more detail, open File > Examples > SD > SdFat_Usage.

LittleFS for Files on Flash Chips

A LittleFS library is now included, providing littlefs published by ARM with a set of drivers for common memory chips and a high-level API compatible with the Arduino SD library.

Before 1.54, only the SerialFlash library was used for flash memory chips on Teensy. SerialFlash provides essentially raw access to the underlying flash memory, which gives best performance, but comes with many limitations. In particular, files must be created with a fixed size and can not grow in size beyond their original allocation.

LittleFS provides a traditional filesystem. Files may be written as you would with the Arduino SD library. LittleFS has flash memory wear leveling and copy-on-write behavior to protect against filesystem corruption if power is lost while writing, so LittleFS is a good choice for data logging or other applications which regularly write. However, the copy-on-write behavior does impose overhead, making LittleFS slower than SerialFlash.

LittleFS supports flash memory chips on both the QSPI memory area of Teensy 4.1 and connected to the SPI ports. FRAM memory chips are only supported on SPI ports. Teensy’s built in memory can also be used.

These are the supported memory types with LittleFS in Teensyduino 1.54.

- Winbond W25Q16JV*IQ / W25Q16FV

- Winbond W25Q32JV*IQ / W25Q32FV

- Winbond W25Q64JV*IQ / W25Q64FV

- Winbond W25Q128JV*IQ / W25Q128FV

- Winbond W25Q256JV*IQ

- Winbond W25Q512JV*IQ

- Winbond W25Q64JV*IM (DTR)

- Winbond W25Q128JV*IM (DTR)

- Winbond W25Q256JV*IM (DTR)

- Winbond W25Q512JV*IM (DTR)

- Adesto/Atmel AT25SF041

- Spansion S25FL208K

- Winbond W25N01G

- Winbond W25N02G

- Winbond W25M02

- Cypress CY15B108QN-40SXI

- Cypress FM25V10-G

- Cypress FM25V10-G rev1

- Cypress CY15B104Q-SXI

- ROHM MR45V100A

- Teensy 4.0, 4.1, MicroMod Program Flash

- RAM Disk, internal RAM or PSRAM on Teensy 4.1

Use of program memory comes with some caveats. While writing, your program may briefly stall when the flash memory is busy with an erase or write operation. Uploading new programs fully erases the flash memory, destroying any saved files. Future Teensyduino may provide a way to preserve the files across code uploading, but in 1.54 all files are lost. Of course, this applies only to program flash. Uploading code doesn’t alter data stored in other flash memory connected to the SPI ports or QSPI memory expansion.

To get started using LittleFS, check out the examples in File > Examples > LittleFS. Documentation and more example code can be found in the LittleFS README file.

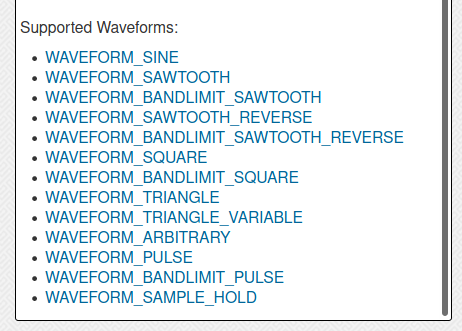

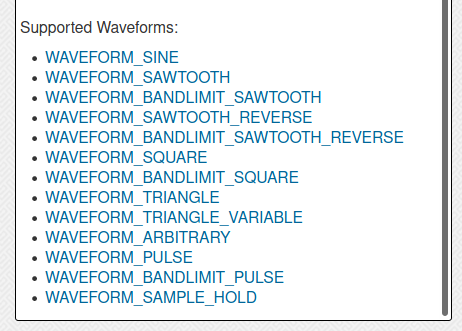

Audio Bandwidth Limited Waveforms

Audio waveform synthesis now supports bandwidth limited sawtooth, square, triangle and pulse waveforms, thanks to a contribution from Mark T.

These are the waveform types now supported by the waveform synthesis object.

Bandwidth limited waveforms are useful when another waveform rapidly modulates frequency, phase or amplitude. Modulation creates additional spectral content. With standard full bandwidth waveforms, this new sound content can suffer from Nyquist aliasing. Using bandwidth limited waveforms can avoid those aliasing problems.

Some people also feel the bandwidth limited waveforms simply sound better, or “more musical”.

Now you can have either standard or bandwidth limited waveforms, simply by changing the waveform name. However, the bandwidth limited versions do require more CPU time. Teensy 4.0, 4.1 or MicroMod are best for polyphonic synthesis where many bandwidth limited waveforms may need to be synthesized simultaneously.

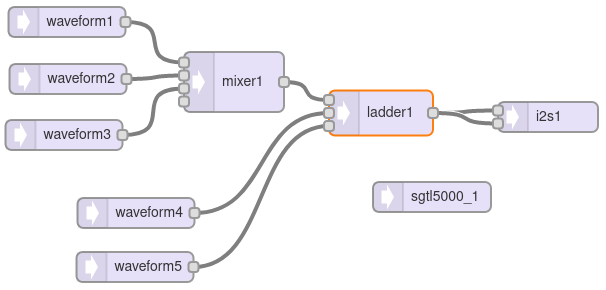

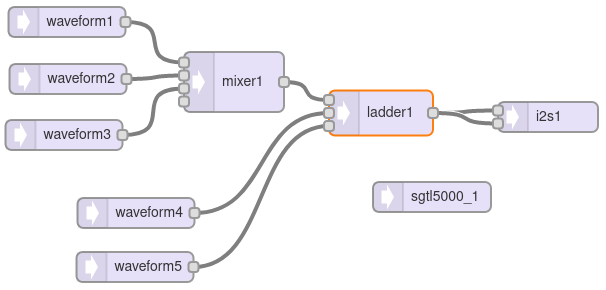

Audio Ladder Filter

The audio library now includes a low-pass ladder filter, thanks to a contribution by Richard van Hoesel, based on the Oscillator and Filter Algorithms for Virtual Analog Synthesis paper published by Vesa Välimäki and Antti Huovilainen in Computer Music Journal 2006.30.2.19.

This ladder filter attempts to provide classic Moog sound when used with subtractive synthesis, where complex waveforms are generated with rich sound spectrum and then filtered, often using other waveforms to dynamically alter the filter’s parameters.

The ladder filter has 3 inputs, for the signal to filter, a control signal which can modulate the filter’s corner frequency, and another control signal which can modulate the filter’s resonance.

Like the original analog Moog filter, resonance can be adjusted or modulated all the way to cause self oscillation. Many classic synthesizer sounds make use of this self oscillation feature.

Internally, this ladder filter uses hyperbolic tangent approximation and 4X oversampling to simulate the non-linear behavior of the original analog Moog filters. An inputDrive() function is available to adjust the response from a very “clean” sound to the “dirty” overdrive mode popular with the Minimoog Model D synthesizer.

To quickly hear the ladder filter, open File > Examples > Audio > Synthesis > LadderFilter.

The ladder filter is numerically intensive. While it technically can run on Teensy 3.5 & 3.6, for practical usage Teensy 4.0 should be considered the minimum required hardware.

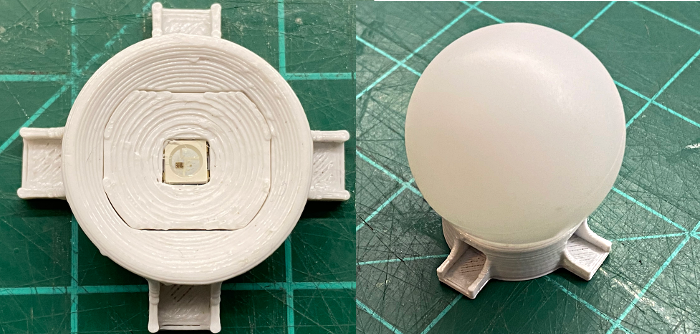

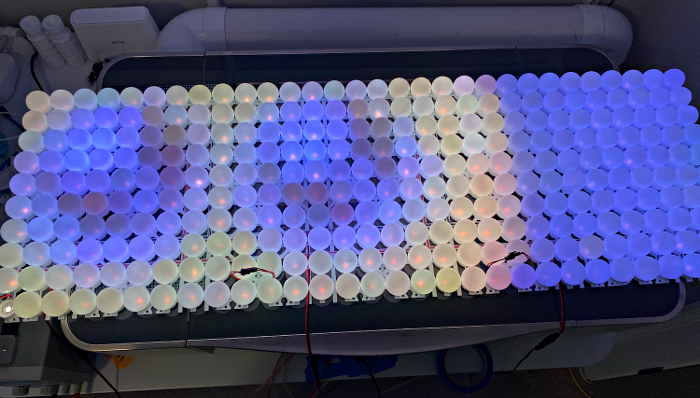

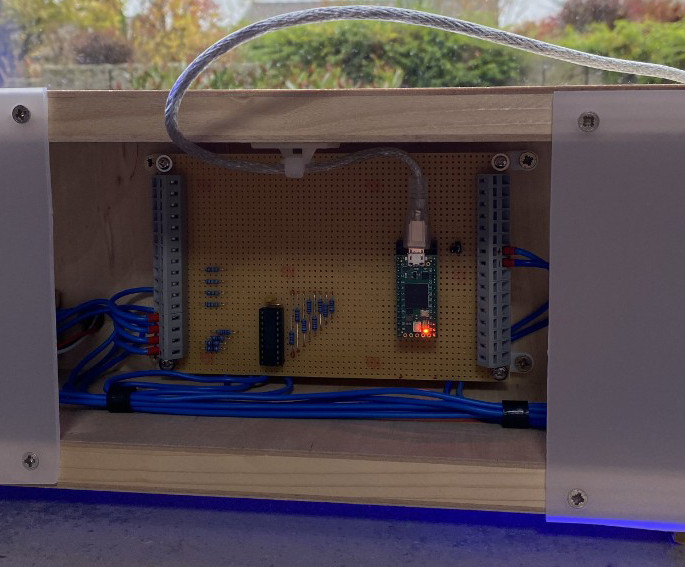

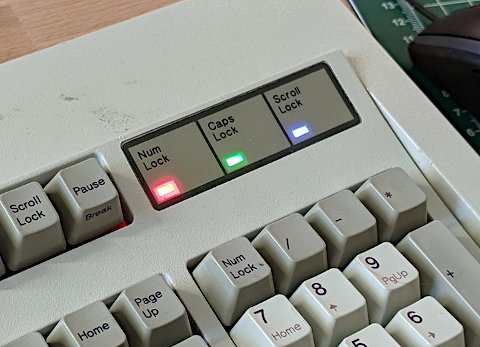

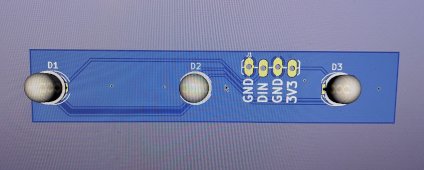

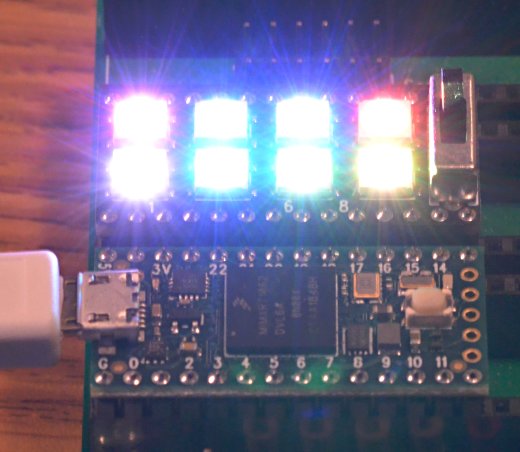

RGBW LEDs

Both WS2812Serial and OctoWS2811 now fully support WS2812, WS2812B, SK6812 or “NeoPixel” RGBW addressable LEDs. The additional white LED allows creation of pastel-like colors, and reliable white at greatly reduced power consumption.

These libraries use Direct Memory Access (DMA) to avoid blocking your program from running while the LED data is transmitted at 800 kbit/sec. The non-blocking behavior gives your program more time to compute complex animations between LED updates. It also prevents interference with audio, serial communication, or other libraries requiring interrupts.

On Teensy 4.0, 4.1, and MicroMod, OctoWS2811 can use any combination of digital pins, even while using RGBW LEDs, rather than only a fixed set of 8 pins as with older Teensy models. For details, open File > Examples > OctoWS2811 > Teensy4_PinList. Both libraries now include examples for RGBW. If switching from RGB to RGBW, be sure to copy or update the buffer memory definition, as 4 bytes are needed for each LED rather than only 3.

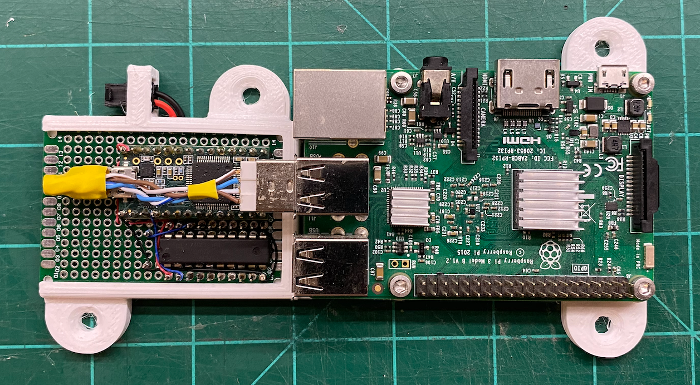

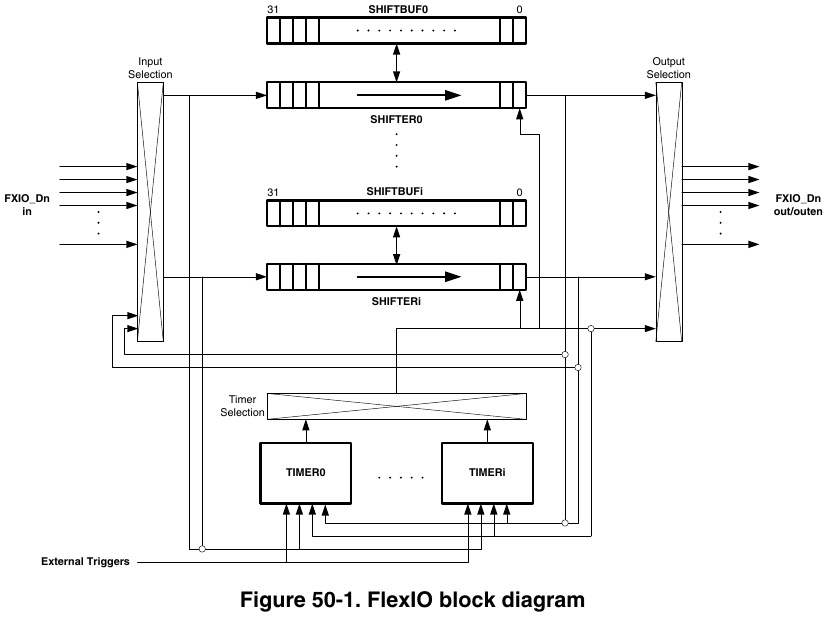

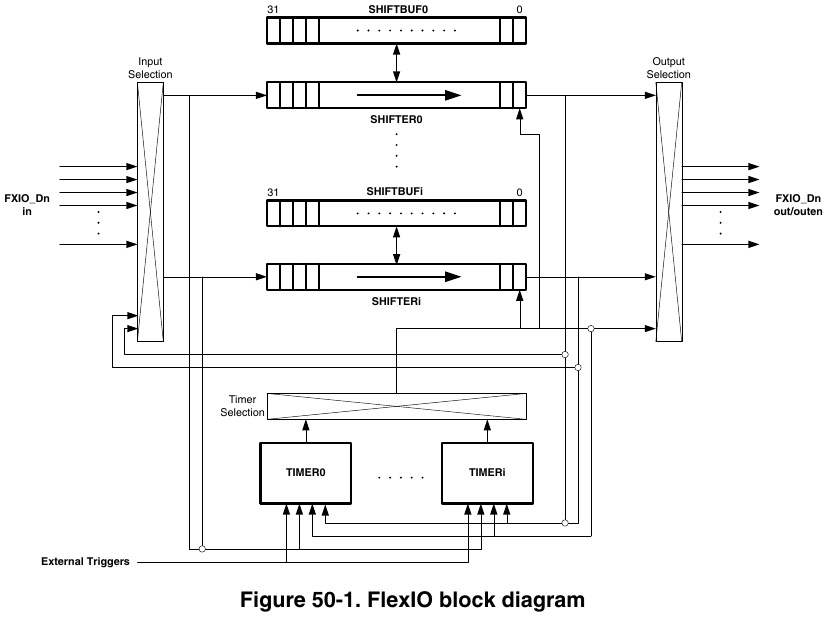

FlexIO_t4 Library

FlexIO provides a sort of construction kit for building custom communication peripherals, using 32 bit shift registers, 8 & 16 bit timers, special control logic, and configurable signal routing to I/O pins.

Each FlexIO port provides 8 shift registers and 8 timers. The IMXRT1062 chip on Teensy 4.0 has 3 of these FlexIO ports.

Teensyduino 1.54 now includes the FlexIO_t4 library written by Kurt E.

First, this library provides objects for FlexSerial and FlexIOSPI classes, so you can create even more SPI and Serial ports, beyond the regular 8 serial ports and 3 SPI ports!

Second, the library provides dynamic resource management for the shifter & timer resources within each FlexIO port. The goal is for libraries using FlexIO, such as TMM-HM01B0-Camera and TriantaduoWS2811, and FlexSerial & FlexIOSPI, to coordinate their usage of the shifter & timer resources. While this resource coordination is still a work-in-progress, ideally in future versions you use any combination of these and other FlexIO libraries, they will automatically resolve which library instances utilize each shifter & timer within FlexIO ports.

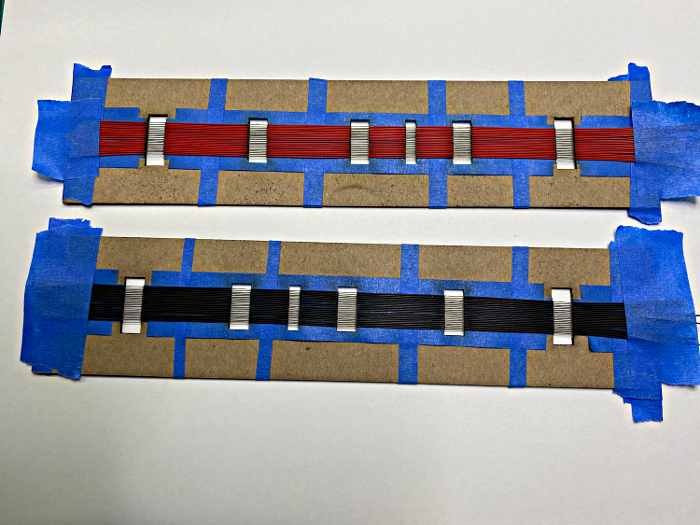

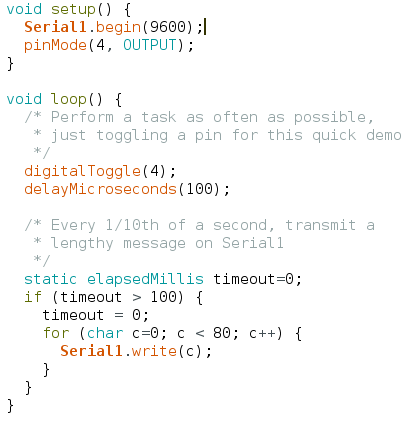

Additional Serial Buffer Memory

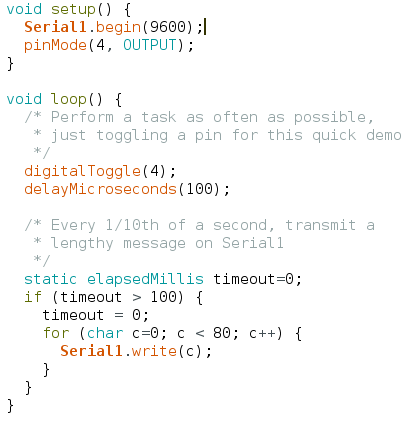

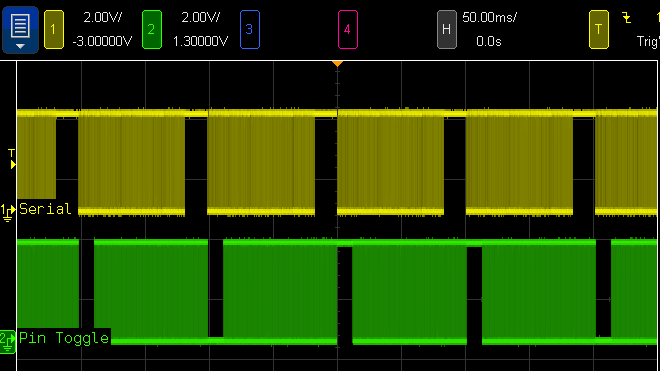

Each hardware serial object, Serial1 to Serial8, has buffers for storing data recently received or ready to transmit. For certain applications, you might like to increase the size of these buffers.

For example, if your loop() function performs tasks which need to happen regularly for proper functioning of your project, but also needs to occasionally transmit a large message on a serial port, the fixed buffer size can become an issue.

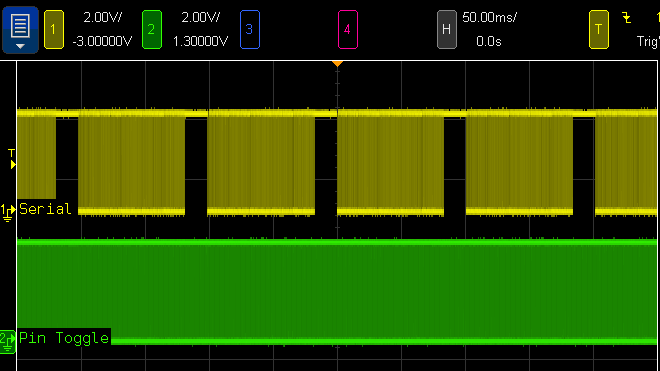

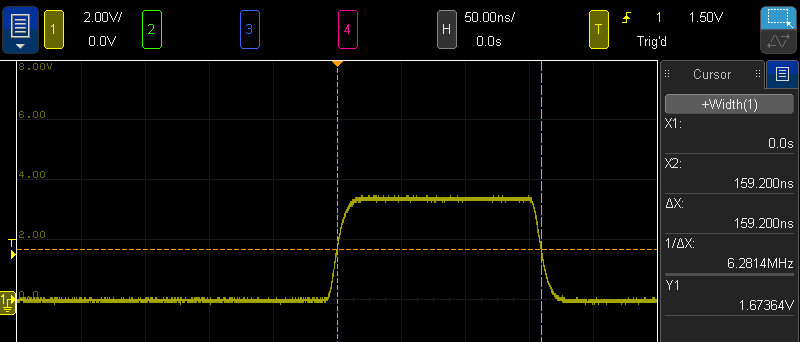

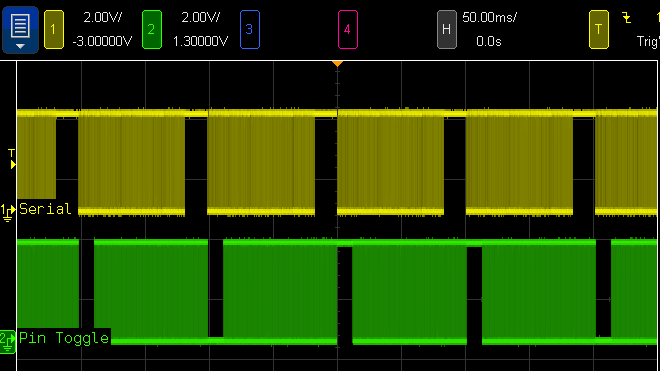

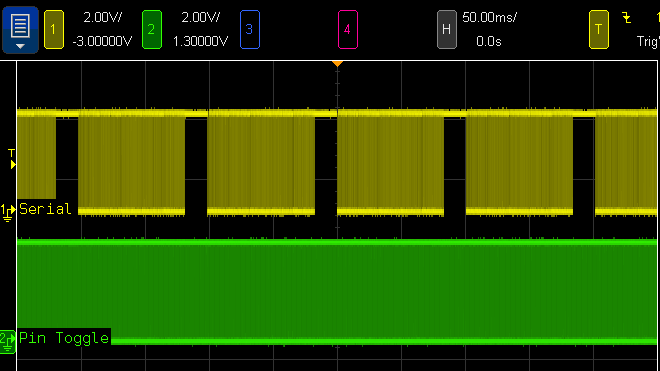

When this simple program is run, indeed the messages appear on the serial TX1 pin (yellow trace below) every 100ms. But at the beginning of each message, pin 4 (the green trace below) stops changing for several milliseconds because Serial1.write() must wait for space in the transmit buffer.

The usual but complex solution to this problem is Serail1.availableForWrite(), which tells you how many bytes can be written without incurring extra delay. However, this requires restructuring your program to write the outgoing message in multiple pieces. If the message contains data which may change over time, perhaps you make a copy of all the data. Doable, but complicated. Everything would be so much simpler if you could increase the Serial1 buffer size.

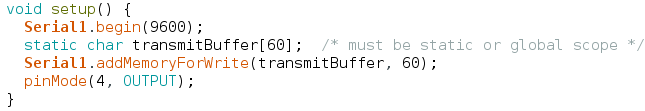

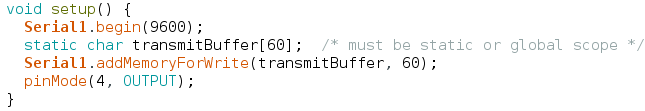

Now you can increase the serial buffer sizes on all 32 bit Teensy boards, thanks to contributions from Kurt E. To increase the Serial1 transmit buffer, you use Serial1.addMemoryForWrite().

You create an array of bytes to serve as the extra memory. The array MUST be either static or global scope, because Serial1 will continue using it long after the current function ends.

When this program is run with extra buffer memory, the green trace never stops. The loop() function never stalls waiting on Serial1.write() because the buffer is now large enough to hold the entire outgoing message.

Of course, you can also increase the receive buffer with Serial1.addMemoryForRead(). If your program spends time doing lengthy computations or other work while serial data is arriving at a high baud rate, extra buffer memory can help avoid the loss of incoming bytes.

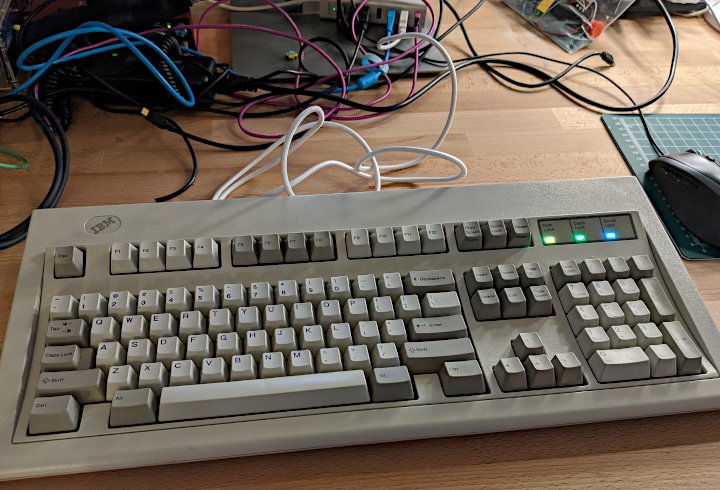

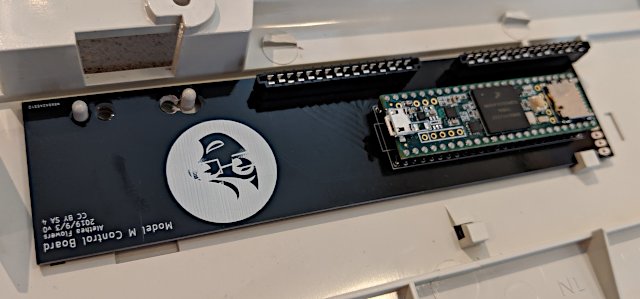

More Serial RX & CTS Pin Choices

Teensyduino 1.54 also brings more choices for which pins to use to receive serial data and flow control signals, on Teensy 4.0, 4.1, and MicroMod. Thanks to another contribution from Kurt E, you can now use pins 0, 1, 2, 3, 4, 5, 7, 8, 30, 31, 32, 33 with any of the Serial1 to Serial8 setRX(pin) and attachCts(pin) functions.

Normally the serial signals connect to the pins through a multiplexer which allows 1 of 8-10 peripherals to control the pin. This new feature automatically routes the serial receive and CTS receive signals through the “XBAR” (crossbar trigger network) peripheral to open up many more choices than could be configured using only the normal pin multiplexers.

This is particularly valuable for use of hardware RTS / CTS flow control, which allows fast baud rates up to 6 Mbit/sec to be used reliably with “normal” programs which may not always read incoming data rapidly. Serial1 to Serial8 support transmitting RTS on any pin, but with prior software, only Serial3 and Serial5 on Teensy 4.x could receive CTS (and Serial5 only supported CTS on a SD card pin). Now RTS / CTS flow control can be used easily with any of the 8 serial ports.

One caveat, however, is each serial port may only route one input signal through the XBAR peripheral. For each serial port, you may use either setRX() or attachCts() with these special XBAR pins, but not both.

Improved map()

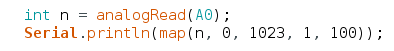

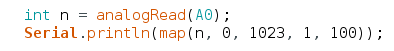

Arduino’s map() function provides a convenient way to scale a number from one range to another. One common use is scaling the analog input pins, which give 0 to 1023 with default settings, to another range, such as 1 to 100.

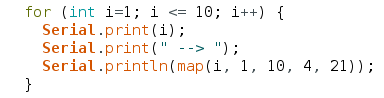

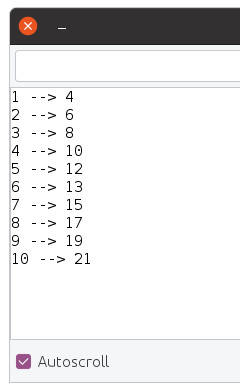

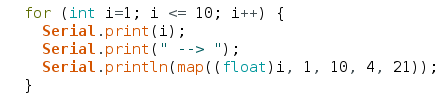

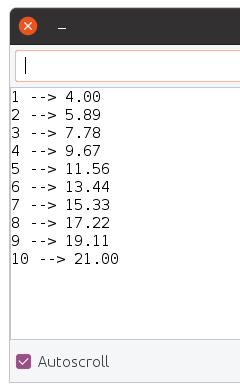

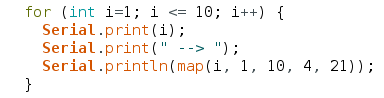

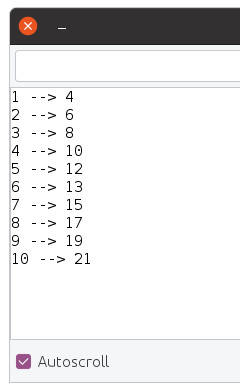

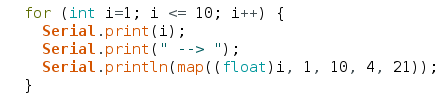

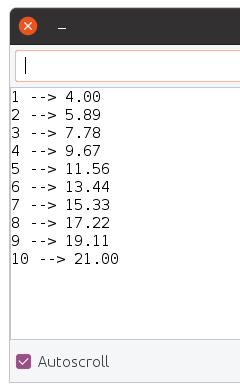

Traditionally, map() has worked only with integer numbers. For example, mapping 1-10 to 4-21:

Sometimes you may want more precision. With Teensyduino 1.54, map() now automatically uses floating point math, if the input variable is float or double type. You can store your number into a float variable, or convert it to float right at the map input.

Of course, if you want the traditional integer-based map(), simply use an integer type for the input. Internally, a little C++ template magic is used to automatically use the integer version when your input is an integer type, or the float version when your input is float or double. If using 64 double, the math is done with full 64 bit precision.

Arduino map() has a long history of suffering integer round-off errors. For most applications, these errors are small and never noticed. But they are errors nonetheless.

Teensyduino 1.54 fixes the integer map() equation, so the integer results agree with the precise floating point results, when the float numbers are properly rounded to the nearest integer.

delayNanoseconds() on all Teensy Models

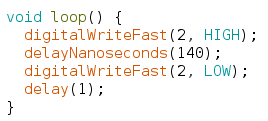

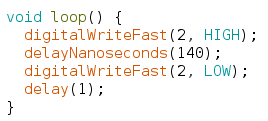

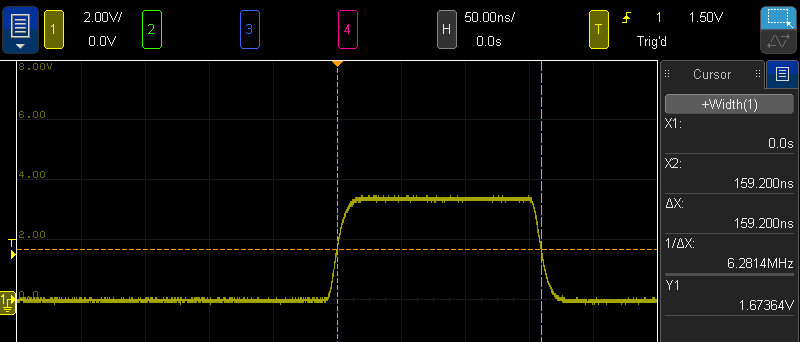

All Teensy models now have a delayNanoseconds() function, even on Teensy 2.0. When you need a very short delay, this function is simple and easy to use.

Often the actual delay will often be slightly longer than requested. Just like delayMicroseconds() and delay() for milliseconds, it will always delay for at least the time specified.

In this simple example, a 140ns delay is used between changing a pin. The actual resulting pulse measures 159ns.

Internally, delayNanoseconds() is implemented differently on Teensy 2 & 3 than on Teensy 4. The older boards use a simple busy loop with “nop” instructions. This gives the best performance on those older & simpler architectures. But if an interrupt occurs during the delay time, the delay continues after the interrupt without any awareness its total time was lengthened.

Teensy 4 has a very different delayNanoseconds() implementation. Because Cortex-M7 relies on caching both data and instructions, and uses multiple types of memory with very different latency for cache misses, busy looping is not as predictable as with the older architectures. Instead, the desired nanoseconds are converted to CPU cycles, and the a wait loop polls the ARM DWT cycle counter. While this adds overhead before the delay begins, the result is highly predictable results regardless of memory & cache. An added benefit is resilience to interrupts which may occur during the delay.

Normally delayNanoseconds() is used with a constant input for the nanosecond time. Inline code is used, where the compiler is able to better optimize results when the input is a constant. However, variables not known as constants at compile time may be used. All 32 bit boards still give fairly good results. On Teensy 2.0, use of variable input results in delay precision of about 1 microsecond.

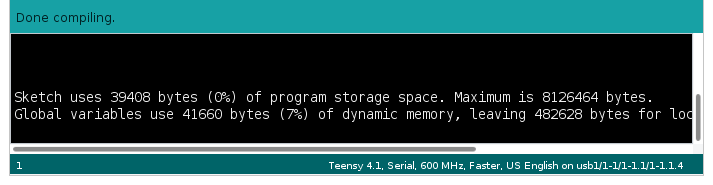

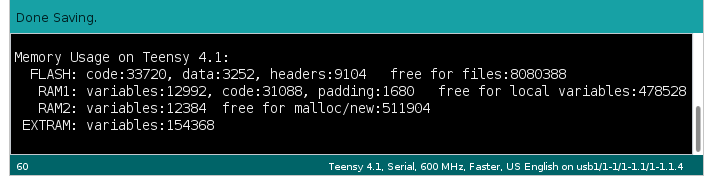

Detailed Memory Usage Report

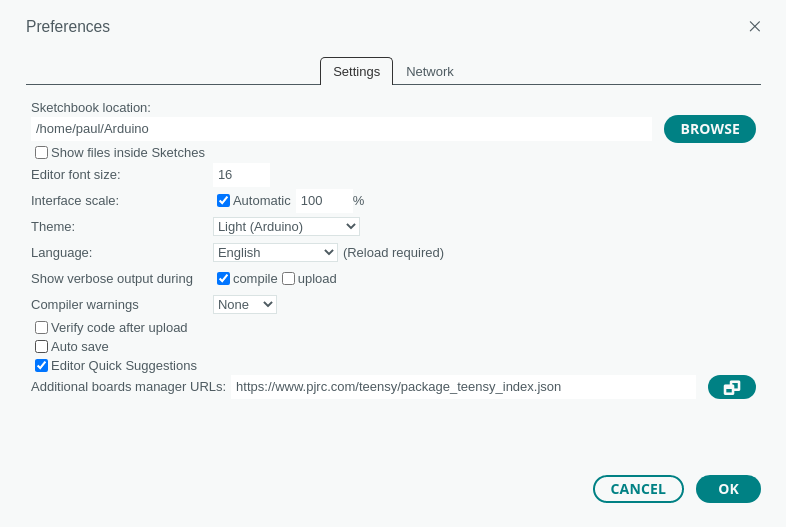

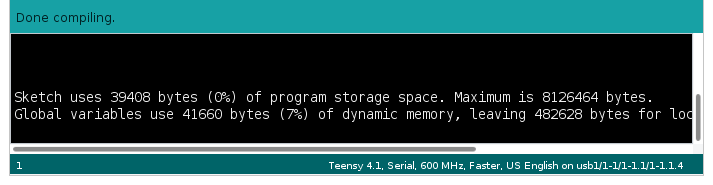

Prior Teensyduino versions used Arduino’s default memory usage summary after compiling.

For Teensy 4, this simple memory report leaves much to be desired.

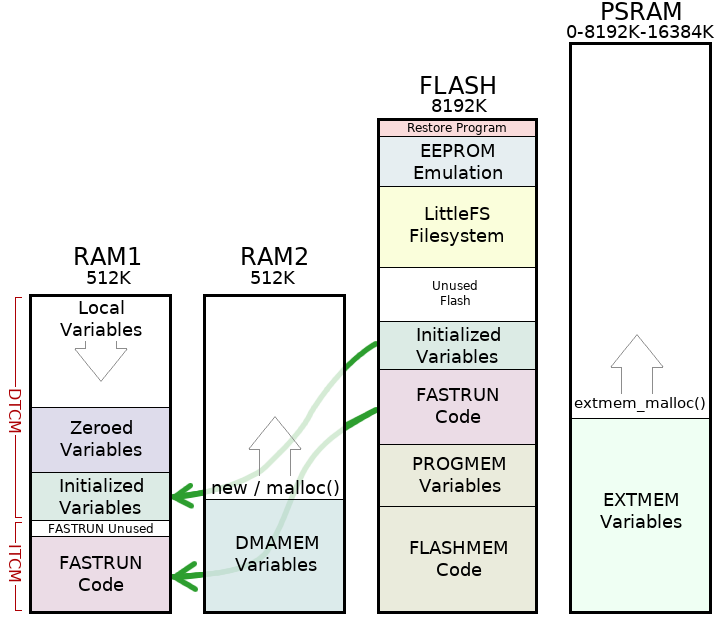

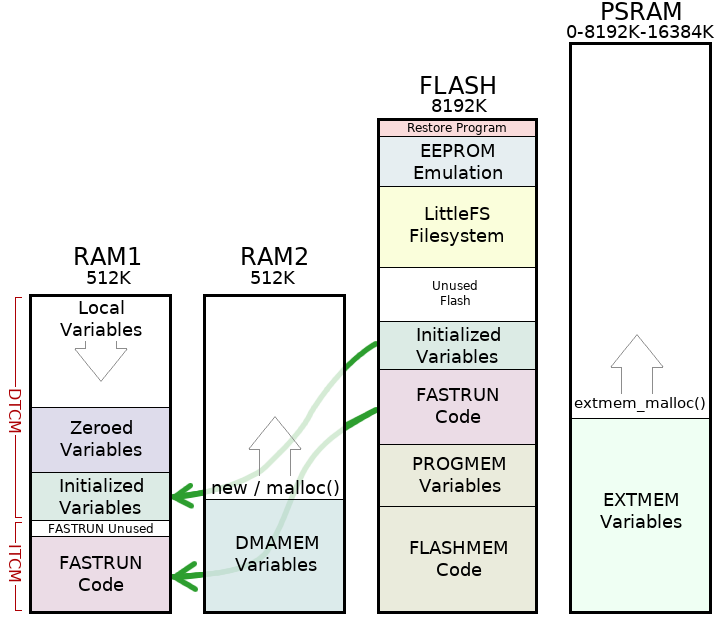

Teensy 4.0 & MicroMod have 3 distinct memories. Teensy 4.1 has 4 distinct memory areas, if PSRAM chip(s) have been added.

Arduino’s simple memory usage also assumes RAM is only used for variables and flash is only used for code. On Teensy 4 boards, the RAM1 memory is partially used for code. Because the hardware supports partitioning RAM between Instruction Tightly Couple Memory (ITCM) and Data TCM in 32K blocks, a portion of the last 32K block of ITCM is unused padding.

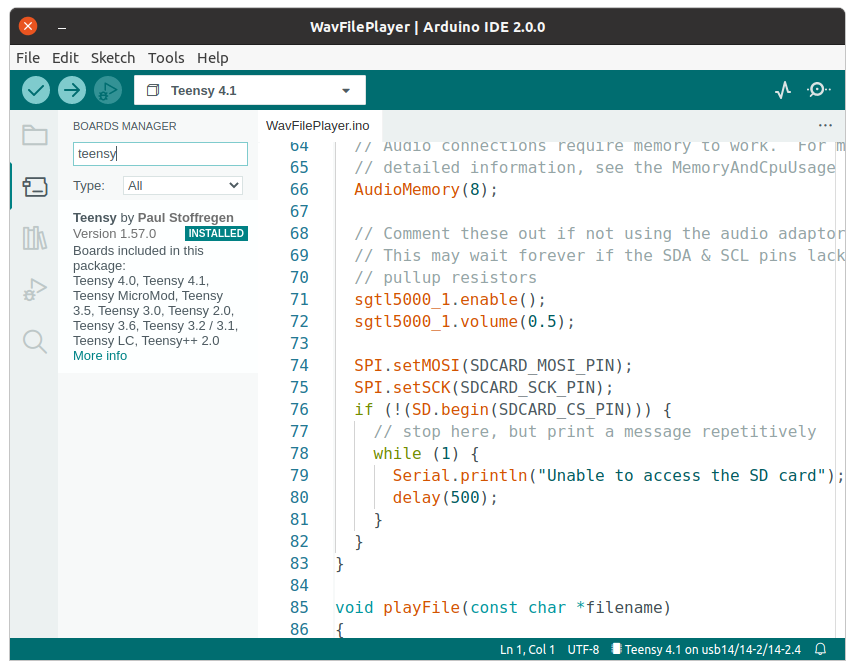

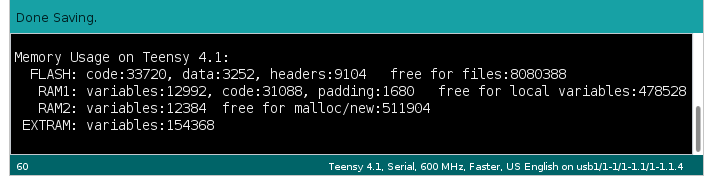

Teensyduino 1.54 brings a more detailed memory usage summary which shows how each of the 3 or 4 memory regions are actually used.

Flash memory usage is given in more detail. One common issue is large arrays of constant data, such as lookup tables to speed computations or digital media like sound clips & fonts, can be mistakenly allocated to RAM. The report now shows how much is data versus code, so you can easily see the change in data stored in flash while working with such const data arrays.

A portion of flash memory usage is reported as “headers”. Slightly over 4K at the beginning of flash memory is reserved for data used by the IMXRT startup process. 3K at the end of your program is reserved for a digital signature. Up to 2K of padding may be used to align these areas to 1K boundaries. By reporting these as “headers”, they’re not mixed in with the code and data your program uses, giving you a more accurate view of how your program is really using the flash memory.

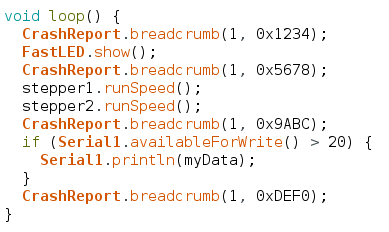

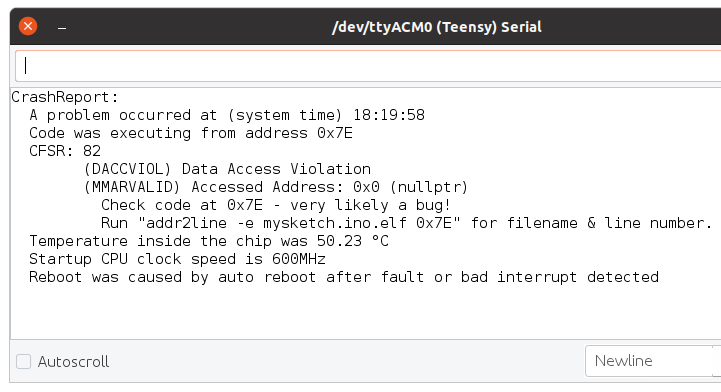

Fault Recovery & CrashReport

Teensy 4.0, 4.1 & MicroMod have a Memory Protection Unit (MPU) built into the ARM Cortex-M7 processor. The MPU allows permissions and caching configuration to be established on up to 16 memory regions. This is much simpler than a Memory Management Unit (MMU) found in PCs, which translates addresses to implement virtual memory. The MPU only enforces permissions, such as whether reading, writing or code execution is allowed in each memory region.

Since the earliest Teensy 4.0 beta tests, the MPU has been configured with security conscious settings, such as only allowing code to execute from flash and ITCM memory regions and disallowing any access from a NULL pointer. But if your program “crashed” by violating any MPU permissions or otherwise caused a fault exception, the default fault handler was essentially empty. Teensy 4.0 & 4.1 would stop responding and a press of the pushbutton was needed to recover.

Teensyduino 1.54 includes an improved default fault handler to recover from problems and give you information to help diagnose what went wrong. The new fault handler performs these actions.

- Log processor state & other useful info to RAM

- Reduce CPU speed to 198 MHz

- Complete USB transmission, so all Serial.print() data buffered before the fault (hopefully) arrives at the Arduino Serial Monitor

- Try to remain USB responsive to Arduino’s Upload button

- Automatically reboot after 8 seconds

Because this fault handler is built into all programs, and because it runs when something has gone very wrong, its code is meant to be kept simple & small. Diagnostic info is written to a fixed location in RAM (which is preserved when restarting), rather than communicated at the time of the fault.

The automatic reboot may controversial. Rebooting tends to hide the fact a problem occurred. For most applications where Teensy always runs an application specific program, automatically restarting to recover from a problem is probably better than remaining forever unresponsive.

The 8 second delay was chosen for 2 reasons. Traditionally watchdog timers are used for automatic rebooting. If any of the 3 watchdogs are in use, they can function normally if configured for less than 8 seconds. The 8 second delay is also meant to prevent a rapid infinite rebooting loop in the case where the program quickly causes another fault. Hopefully 8 seconds is a good balance between promptly recovering, avoiding difficult to understand reboot-loop behavior, and allowing normal watchdog usage.

After Teensy reboots, your program can access the logged information with CrashReport. The CrashReport code is only built into your program if you actually use it. While your program can use CrashReport at any time, it is meant to be used early in your program’s startup, hopefully before anything has gone wrong, so you have fully access to a freshly rebooted system.

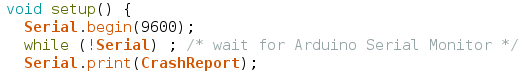

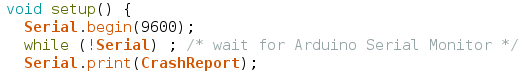

The simplest CrashReport usage is with a single Serial.print() line.

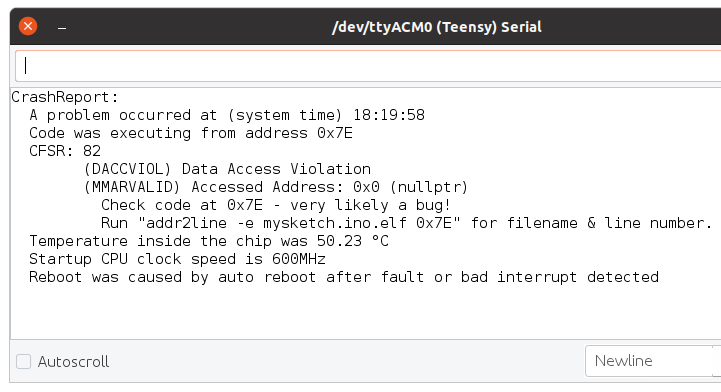

If your program previously crashed with a fault or unused interrupt which logged information, CrashReport shows you a summary.

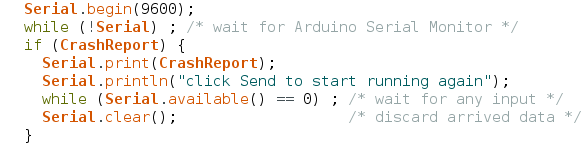

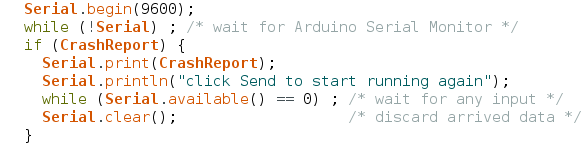

CrashReport can be tested as true/false, to tell you whether information was logged. You might use this with a program that rapidly prints to the serial monitor, to show the info and wait for input before continuing on to run the program which quickly scrolls the CrashReport info off your screen.

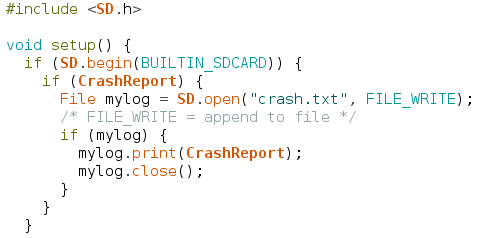

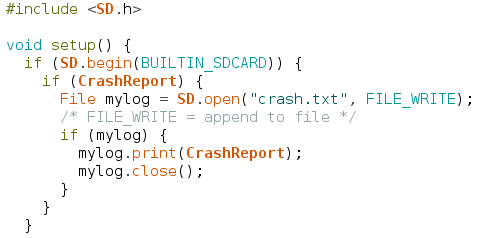

CrashReport is not limited to use with only the Arduino Serial Monitor. It can be used with any interface inheriting the Arduino Print class. For example, you can store CrashReport to a file on a SD card or a flash chip with LittleFS, to keep a record of every time a fault was detected.

The default fault handler and CrashReport can not handle every possible error. The MyFault library was created as a collection of test cases for fault recovery and CrashReport, and also has a typical usage example.

Bug Fixes and Minor Improvements

Teensyduino 1.54 also includes many bug fixes, minor features & improvements, and updated libraries. A detailed list of all changes can be found on this forum announcement thread.